Plant safety and Forms

Pressure equipment: Legal requirements for the commissioning of tanks

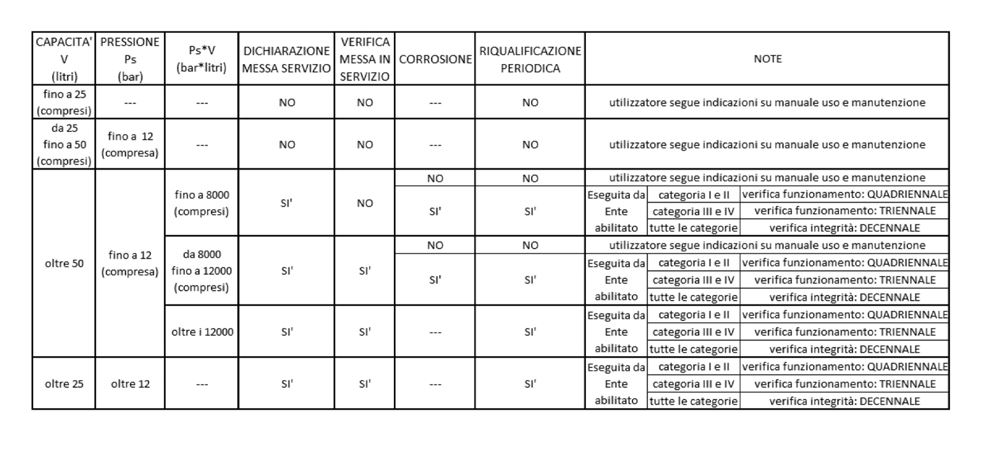

DM 329/04 provides for the notification of putting into service of the pressure vessel whenever we are in the presence of :

- new system

- modified installation (new components added)

- relocated plant

Every user of pressure equipment (compressors with oil separating tanks, pressure tanks, compressed air systems, etc.) referred to in art. 1 of Ministerial Decree no. 329 of 01.12.2004 must submit the following documentation to the competent bodies (INAIL ex ISPESL and AUSL):

- Request for verification of commissioning

- Notification of commissioning of the system and its annexes (technical report of the system, system diagram, declaration signed by the employer regarding compliance with the installation instructions of the equipment)

- Obligation of verification of periodic upgrading of equipment

Article 15, paragraph z) of Legislative Decree 81/08 and subsequent amendments and integrations, provides for the regular maintenance of environments, equipment and plants, with particular regard to safety devices in accordance with the manufacturers’ instructions.

Art. 71 of Legislative Decree 81/08 and subsequent amendments and integrations, provides for the obligations that the employer must adopt in order to secure the work equipment supplied to its workers.

Ministerial Decree 11/4/2011 regulates the procedures for carrying out the periodic checks referred to in Annex VI of Legislative Decree no. 81 of 9 April 2008 by the owners (INAIL, AUSL and Qualified Bodies).

Periodic requalification checks

Art. 12. – DM 329/04 – Integrity checks (every 10 years) during periodic checks

The integrity check consists in inspecting the various members by means of a visual inspection carried out from the outside and from the inside, where possible, in thickness checks and any other checks that may be necessary in the face of obvious situations of damage.

Art. 13. – DM 329/08 – Verification of operation (every 3-4 years) on the occasion of periodic checks

The function test consists of verifying that the conditions of actual use meet the requirements of the startup declaration and verifying the functionality of the valves and safety accessories.

The Legislative Decree 81/08 provides for the regular maintenance of environments, equipment, plants, with particular regard to safety devices in accordance with the indications of the manufacturers.

Art. 13 of D.M. 329/04 provides that every 3/4 years a periodical verification of operation is carried out, which consists in ascertaining the functionality of the valves and safety accessories.

CMC is able to supply certified safety valves covering a wide range of discharge pressures and flow rates.

These figures increase if we consider the numerous processes in which oily wastewater is produced. For this reason, the legislation prohibits the unloading of condensates

and the discharge of oily water into the sewer system