Consumption Analysis

Step 1: Measurement

The instrument used by CMC is able to measure simultaneously the amperometric absorptions up to 4 electrocompressors.

Phase 2: Analysis

Compressor analysis

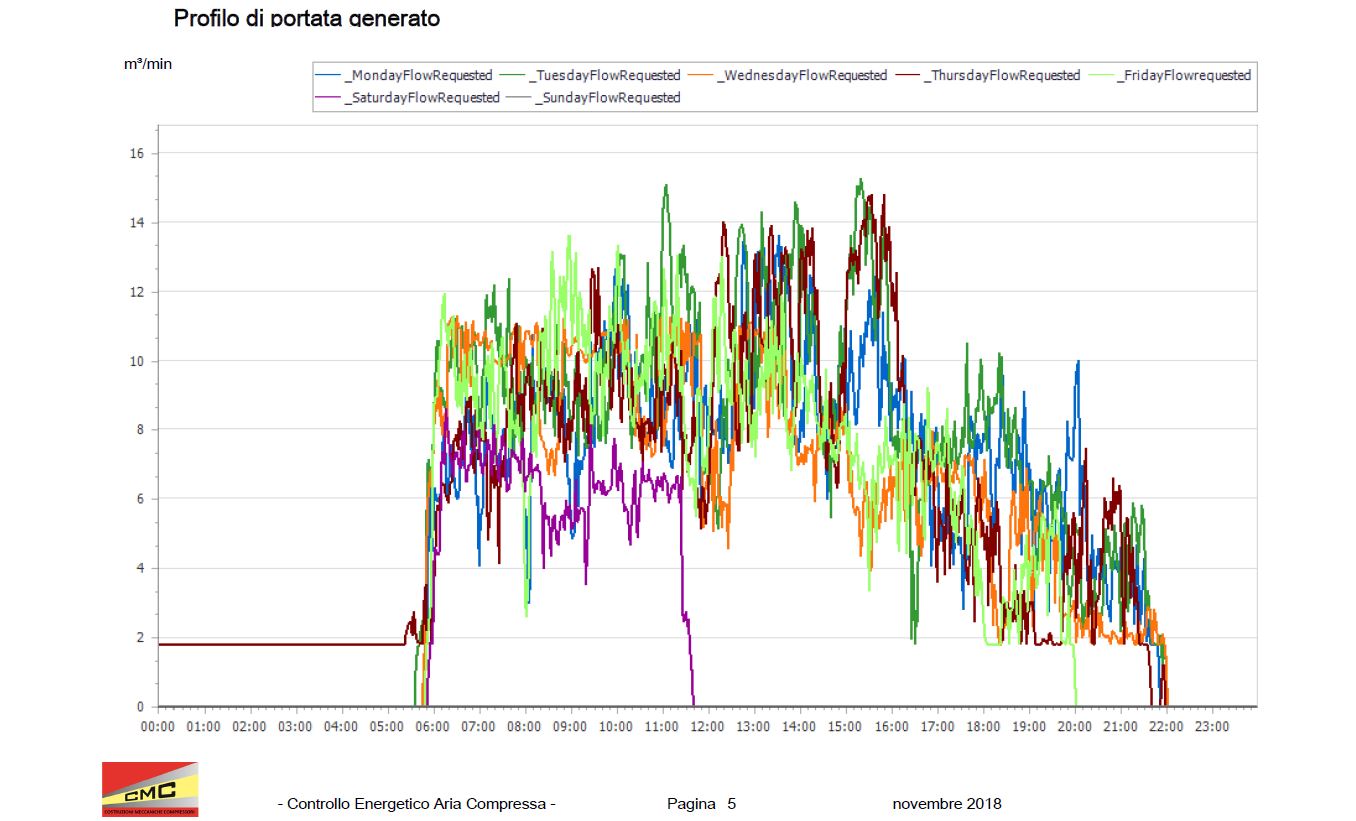

The energy consumption of each individual compressor is measured by means of a current clamp. The flow rate produced is measured directly by means of a mass sensor. These clamps are installed on your compressor in a typical week. We recommend a week with all compressors charged in order to be able to make an annual projection, as truthful as possible.

After entering the nominal values of the measured electrocompressors, the measurement can be used to calculate: percentage of no-load operation, load operation, no-load energy consumption and load operation as well as no-load cycles. We enter a standard kWh cost value and from there it is possible to derive the specific cost of mc of compressed air over a year.

The analysis of the system has the function of identifying the ideal strategy to go to optimize the compressor room and have an energy advantage, indirectly we can also understand the calculation of losses because in the phase of production downtime we can highlight the flow of air required to cover the losses.

Phase 3: Evaluation on the PC with Graphics and Statistics

Once the week is over, we insert the type(s) of compressor into the computer, a graphic evaluation with daily and weekly analysis.

All data are shown in the selected time interval

Compressed air costs in €

All the main measured values can be obtained in both graphical and tabular form:

- Energy costs

- Compressed air costs

- Compressor data with loading/unloading time

- Specific energy in kWh / m³

- Costs per m³ in €

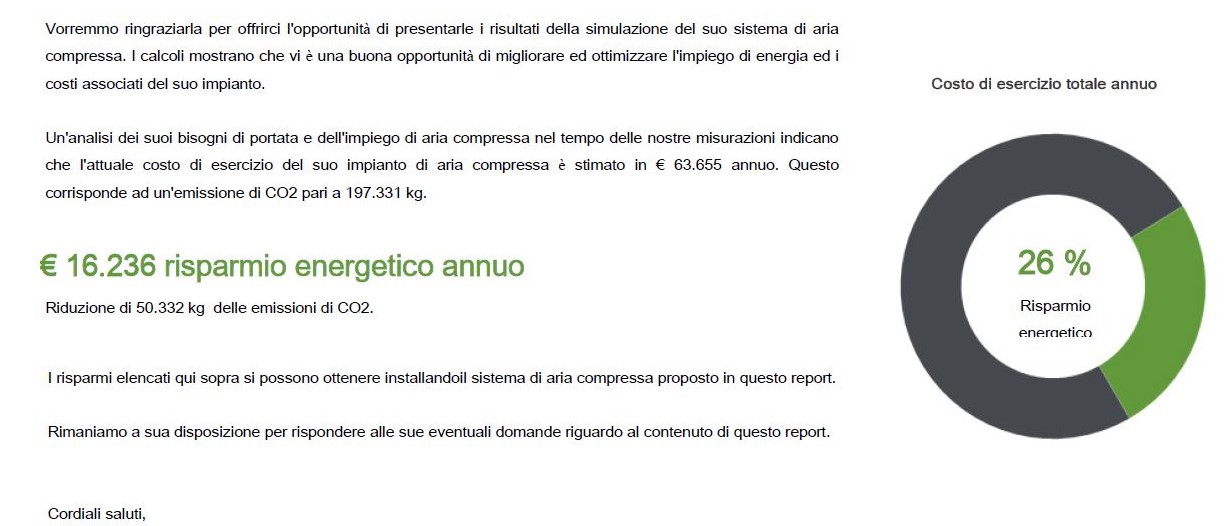

4. Conclusion

On the basis of the analyses carried out in the previous points, it is possible to identify corrective actions to optimise the production costs of compressed air by selecting precisely and selectively all the most suitable tools and activities.